Aircraft Carrier Deck Texture - Saftrax's non-skid coatings are an integral part of Navy flight decks. These coatings provide the surface traction needed to land military jets and keep military personnel safe. Saftrax received a qualification of approval from the Department of the Navy for the Saftrax products TH604 Type I and TH604CF (Chrome Free) Type II.

Our line of non-skid coatings is extremely durable and trusted by the Navy. If you have any questions about our products or the application process, please contact us and our team will be happy to assist.

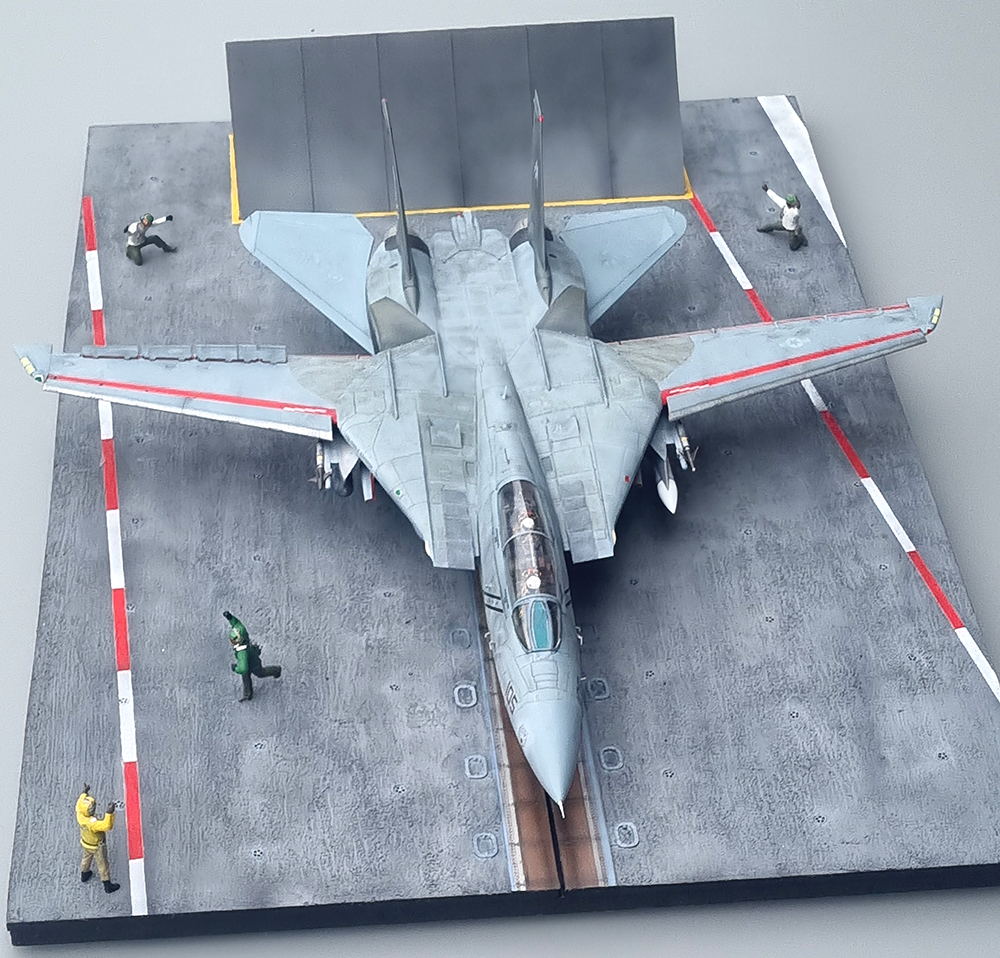

Aircraft Carrier Deck Texture

Let our years of experience in thermal spray help you with your specific non-skid needs. Samples provided upon request. If you have any questions about our products or the application process, please contact us using the form below.

Why Choose Saftrax?

Let our years of experience in thermal spray help you with your specific non-skid needs. Samples provided upon request. The SafTrax line of anti-slip coatings includes TH335, TH604, and TH605, which are ideal for aluminum, cast or ductile iron, stainless steel, and carbon steel surfaces.

They are also suitable for concrete and plastic surfaces. TH604 is a tubular or cored aluminum wire filled with up to 46 percent of aluminum oxide (Al2O3) powder, whereas TH605 is a tubular or cored wire filled with up to 46 percent of silicon carbide (SiC) powder.

TH335 is a tubular or cored wire composed of iron and packed with aluminum and carbon powders. Attain the optimum anti-skid performance needed to bring an aircraft and its occupants to a safe stop on your military or naval flight surface using SafTrax anti-slip thermal spray coatings.

With a coefficient of friction of 1:1 and corrosion-resistant properties, SafTrax military-grade non-slip coatings create a high-traction environment that protects metal substrates from degradation, wear, abrasion, heat, and impact forces. Saftrax's military grade non-slip coatings are resistant to the impact of jet landings and extremely harsh weather conditions.

Anti-Skid Coating Characteristics

These coatings are used for a wide range of defense applications, and some of these common applications include: Payment Method Add a Payment Method Add a Payment Change Method A military grade non-skid coating is a type of coating used on aircraft carriers to provide the traction needed for the flight decks.

These anti-slip coatings are extremely important in both flight operations and for ship personnel safety. DCS: Supercarrier is the most detailed and realistic simulation of a Nimitz-class aircraft carrier ever created. A Nimitz-class aircraft carrier is a nuclear-powered fortress at sea with a crew of over 6,000 sailors and airmen.

The angled flight deck with arrestor wires and four steam-powered catapults support air wing operations of up to 90 aircraft. The ship also includes a formidable air defense system that includes the RIM-7 Sea Sparrow Missile and RIM-116 Rolling Airframe Missile (RAM) missiles, and Close-In Weapon System (CIWS) gun system.

A Nimitz-class aircraft carrier is the ultimate power projection weapon. Innovative technologies in cockpits and aviation towers enable modern aircraft to operate in almost all weather conditions. Superior traction of landing gear tires on the runway surface is vital for a successful touch down or take off.

Why Use Naval Military Anti-Skid Coatings?

Offering an average lifespan of one decade or more, SafTrax aircraft carrier non-skid coatings are a durable and economical solution for naval and military flight surface traction and wear problems. Compliant with the Americans with Disabilities Act and surpassing Occupational Safety and Health Administration non-skid requirements, these coatings create safe work environments, withstand flexing and maintain corrosion resistance when gouged in service.

These military-grade non-slip coatings are frequently used in marine, military, and heavy traffic settings to provide a high traction area for both planes and people. Coating your flight surface with SafTrax coatings is easy and requires zero maintenance.

It is applied using a twin wire arc spray process, which does not require mixing, curing or cording off areas for long periods of time. These military grade anti-slip coatings are ideal for aluminum, cast or ductile iron, stainless steel, and carbon steel surfaces.

They are also suitable for concrete and plastic surfaces.